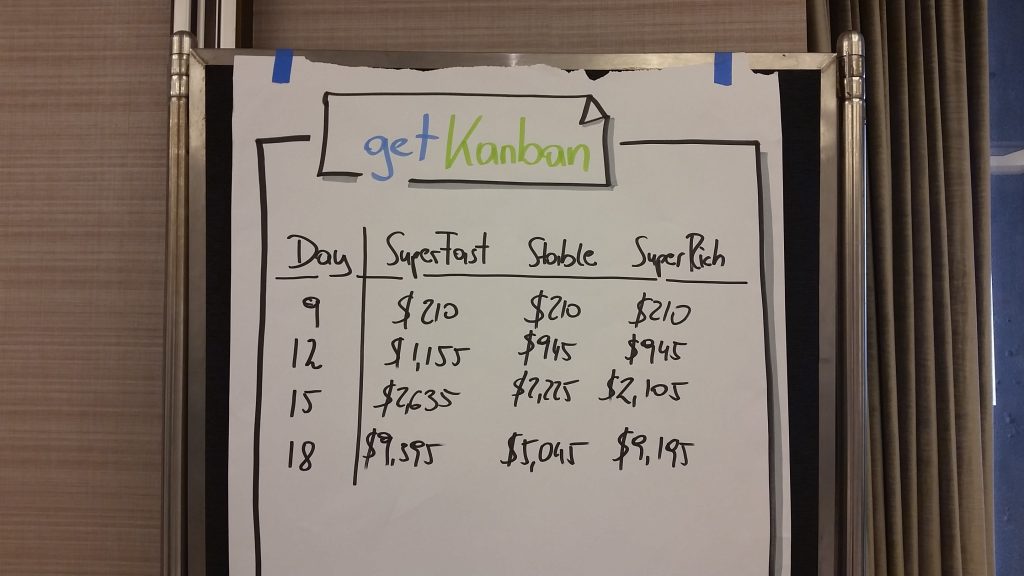

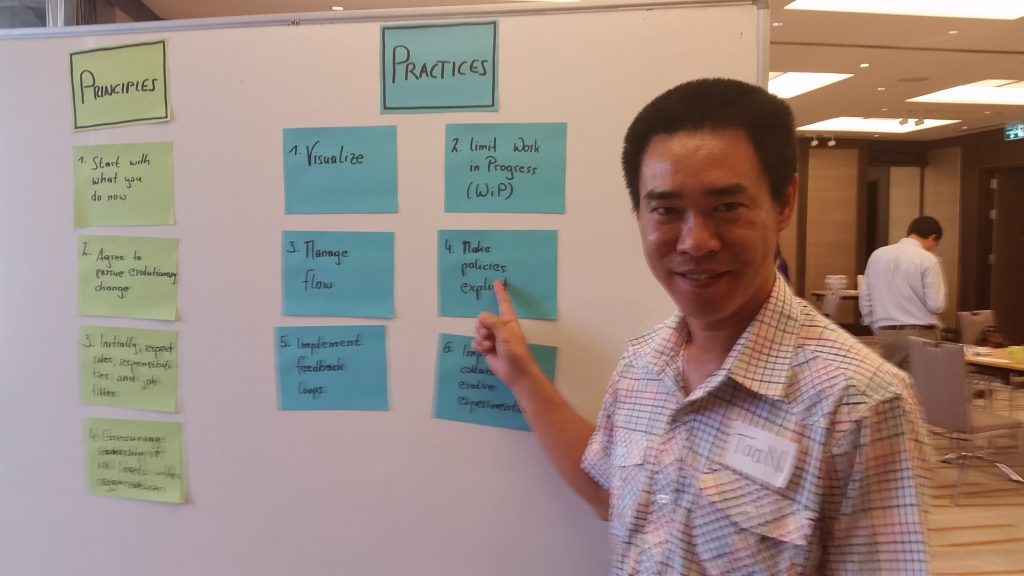

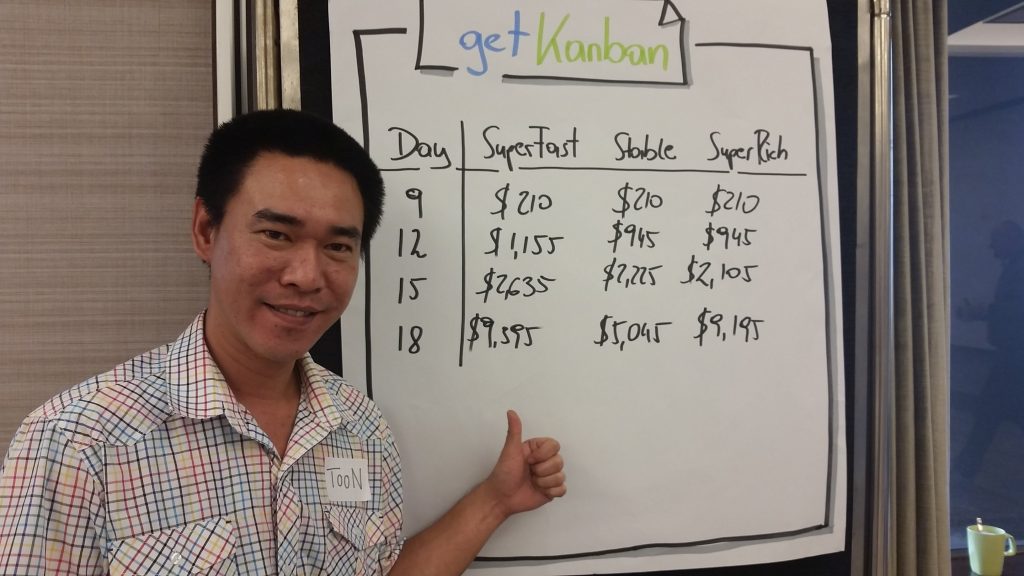

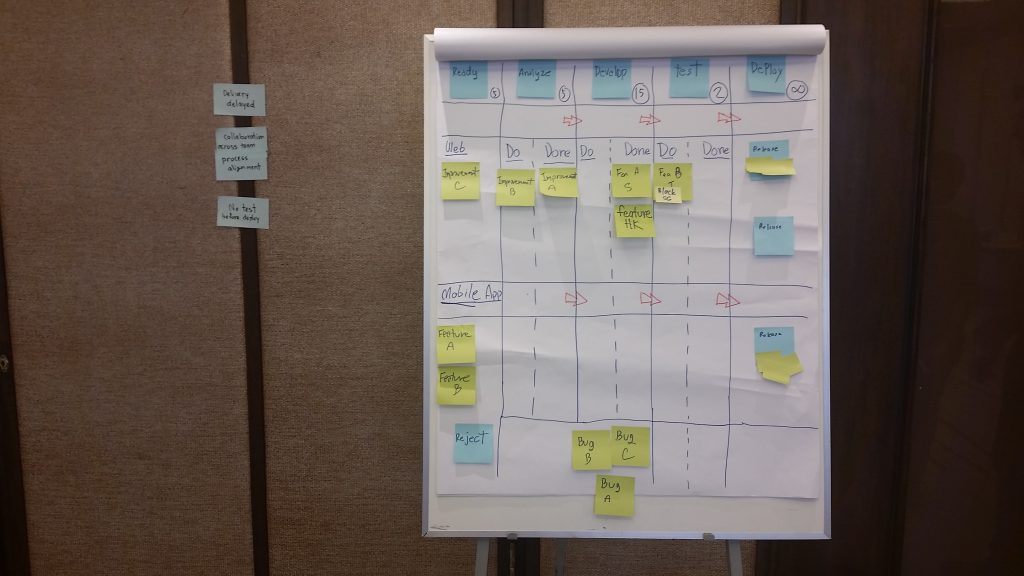

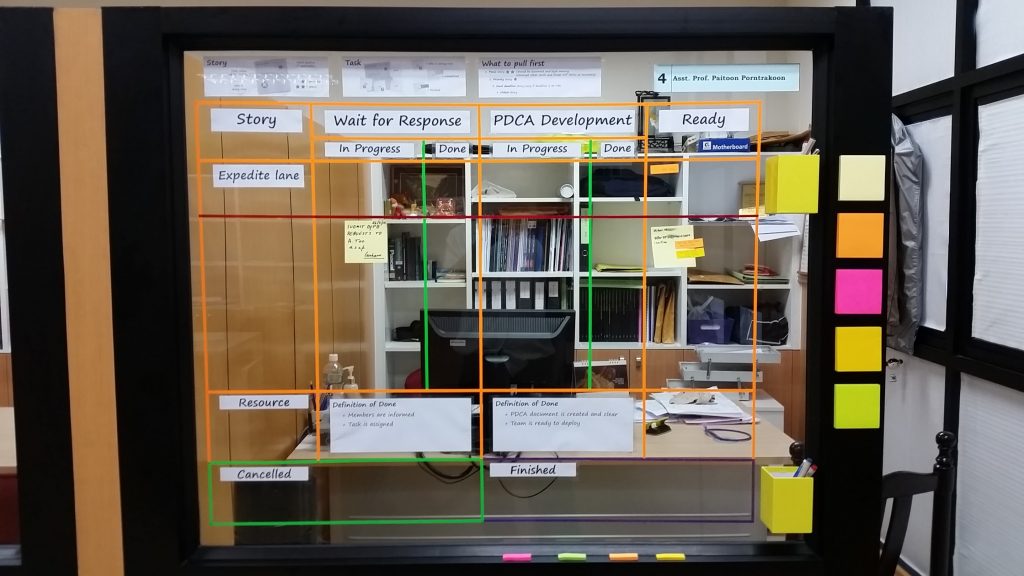

I participated in Kanban training organized by the lean consulting company on Mar. 2-3, 2015. Kanban is a scheduling system for lean manufacturing and just-in-time manufacturing (JIT). Kanban became an effective tool to support running a production system as a whole, and an excellent way to promote improvement. Problem areas are highlighted by reducing the number of kanban in circulation. One of the main benefits of kanban is to establish an upper limit to the work in process inventory, avoiding overloading of the manufacturing system (https://en.wikipedia.org/wiki/Kanban).